What is Antimicrobial Surface Protection?

There has been a LOT of activity recently in the area of antimicrobial surface protection. This is primarily due to the pandemic with the current coronavirus, COVID-19. Companies nationwide and globally are investing their collective energies into killing the COVID-19 virus. As one means of attempting to deal with the outbreak, industries are looking at antimicrobial surface protection. In this article we’ll explain what antimicrobial surface protection is in terms of the technology and practical applications in today’s environment.

There has been a LOT of activity recently in the area of antimicrobial surface protection. This is primarily due to the pandemic with the current coronavirus, COVID-19. Companies nationwide and globally are investing their collective energies into killing the COVID-19 virus. As one means of attempting to deal with the outbreak, industries are looking at antimicrobial surface protection. In this article we’ll explain what antimicrobial surface protection is in terms of the technology and practical applications in today’s environment.

The Science ‘Underneath’ Antimicrobial Surfaces

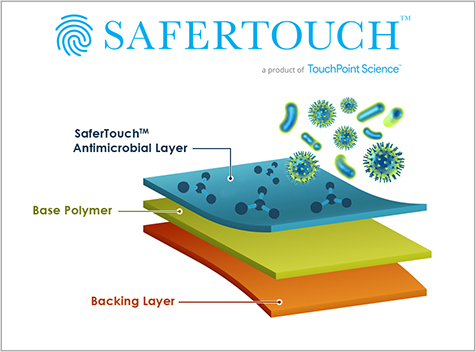

So what is antimicrobial surface protection? The description is as straightforward as it sounds. Built-in or ‘baked in’ antimicrobials (biocides) are typically used in some capacity to try to control bacteria, fungi and viruses on surfaces of materials or finished products. These are applied in a variety of ways, but typically either as a coating or as part of the makeup of the material itself.

In order for the antimicrobials to work, they have to be chosen carefully, added at the optimum concentration, and be available at the surface to control growth of microorganisms in some capacity. Compatibility must also be considered as the chemistries added can have no physical impact to the product or appearance. Most times, antimicrobials surfaces are produced by adding biocides directly to the plastic during molding or manufacturing. Considerations in this approach are complex. There is a balance between antimicrobial performance, and final product attributes that must be achieved. Some antimicrobials yellow the final product. Some antimicrobials will cause ‘blooms’ at the surface where the chemical is actually coming out of solution in the material itself. Some chemistries make the final material brittle. There are many more considerations as well. All of these effects on the final material or product must be carefully evaluated.

So How Does Antimicrobial Surface Protection Work?

The active agents are either added to or coated on the final finished product. These products can be plastics, countertops, door handles, buttons or other surfaces. The intended effect is to kill bacteria, viruses or other organisms that can degrade the material itself.

The antimicrobials are available at the surface to interact with microbes and inactivate them by specific means. They are generally divided into two categories; oxidizers and non-oxidizers. Oxidizing chemistries (such as sodium hypocholite, the active in household bleach) disrupt cell structures and interfere with passing of nutrients to the cell. Non-oxidizing agents react with enzymes or proteins, preventing respiration. They can also break or ‘lyse’ the cell walls of organisms rendering them inactive.

The antimicrobials are available at the surface to interact with microbes and inactivate them by specific means. They are generally divided into two categories; oxidizers and non-oxidizers. Oxidizing chemistries (such as sodium hypocholite, the active in household bleach) disrupt cell structures and interfere with passing of nutrients to the cell. Non-oxidizing agents react with enzymes or proteins, preventing respiration. They can also break or ‘lyse’ the cell walls of organisms rendering them inactive.

Timing is essential for some industries in how antimicrobials work. For example, the food industry is generally seeking fast kill times to prevent spread of contamination. Other industries seek longer term effects, such as on paint coatings, to slowly and consistently prevent the growth of bacteria over time. For antimicrobial surface protection, a balance once again must be attained to provide both quick kill and longer term persistence. Again, when selecting agents, chemical compatibility between the materials and biocides must be achieved.

SaferTouch™ Contains Antimicrobials

TouchPoint Science dedicates its time in evaluating different chemistries, and conducting countless laboratory experiments on novel antimicrobials that could be used in surface protection technology. Our line of SaferTouch™ antibacterial films and antibacterial tapes are the latest in next-generation products designed to cover your most sensitive touch points. The products contain an optimized level of complementary active ingredients designed to produce a synergistic surface effect against the growth of microorganisms, thus protecting the film itself from degradation.

Decades of scientific expertise and industry experience separate our company and our products from the competition. No other antibacterial film or antibacterial tape can compare in terms of effectiveness and longevity. Our films resist degradation by contaminants and are meant to help highlight key touchpoint areas. Please contact our technical staff if you have any questions regarding Safertape™ or any antimicrobial surface protection products from TouchPoint Science. Call us at (470) 300-9804 or use the convenient form below.